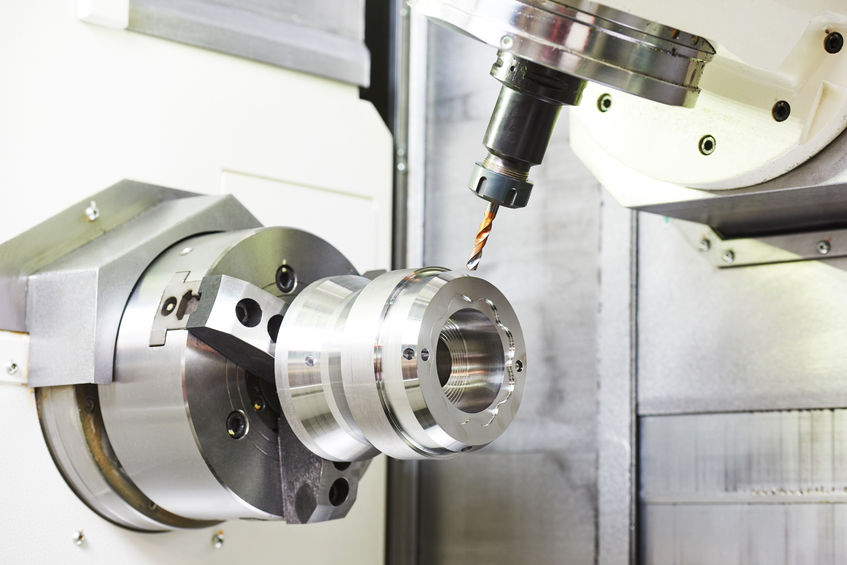

precision machining Fundamentals Explained

It mi…ght be vaguely proper or frequently correct or non-precisely suitable or simply simple Erroneous. You should not acquire this area also very seriously and do your individual investigation. Why folks Never Google initially I do not comprehend. Google the right text and the answer normally will come up pretty swiftly. Engines like google do call for some brains even though to implement. Don't have faith in Wiki Answers fully. (Much more)

Precisely what is machineability? "Device" as a verb basically means to create or manufacture with a equipment - so "machineability" signifies that one thing could be made this fashion.

The flank from the Device offers a clearance involving the Resource and also the recently fashioned get the job done surface area, As a result safeguarding the area from abrasion, which might degrade the complete. This angle amongst the operate area as well as flank floor is called the relief angle. There are two standard sorts of chopping equipment:

5 Simple Techniques For machining

Gang milling was In particular critical prior to the CNC era, since for duplicate component creation, it was a considerable efficiency improvement over manual-milling a single characteristic at an operation, then changing machines (or modifying set up of the exact same device) to chop the next op.

The path with the feed movement is perpendicular into the tool's axis of rotation. The speed motion is provided by the rotating milling cutter. The two simple kinds of milling are:

These voronoi diagrams are utilized for generating the Device path for machining. This technique is regarded as being additional productive and sturdy. In addition, it avoids topological challenges linked to standard offsetting algorithms.[twelve][13]

CNC routers, on the other hand, are perfect for chopping gentle sheet elements which include Wooden and aluminum and are more cost-efficient than using a CNC mill for a similar position. For tougher sheet components including metal, a waterjet, laser, or plasma cutter is necessary.

Wire Electrical Discharge Devices (EDMs) consider an entirely unique approach to CNC machining in that they depend upon conductive supplies and electricity to erode the workpiece. This process can Lower any conductive material, which include all metals.

The Ultimate Guide To precision machining

Many years of industry practical experience has enabled us to supply the best top quality milling machining expert services currently available to our prospects.

In order to avoid Measurement Threat our top quality lab maintains the equipment required to validate the precision capabilities with the gauges employed for each inspection prepare. Instruments Doing the job at peak efficiency support optimize productiveness, profitability and fulfill regulatory requirements.

In turning, a chopping tool with just one leading edge is used to eliminate material from a rotating workpiece to make a cylindrical shape.

Your time is effective. Our on the net quoting and automated CNC machining processes enable for fast-switch machined sections inside of times official source of uploading a CAD product.

The Ultimate Guide To precision machining

Superb customer care. Put an get and obtained an electronic mail inside an hour or so ensuring that I ordered ...the ideal element since I did not require the total magnetomount kit. See Extra